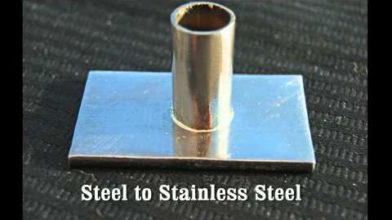

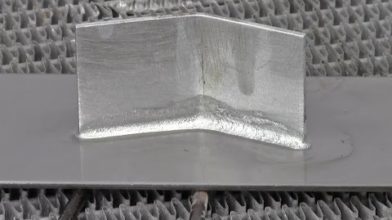

Although stainless steel is one of the most widely used metals, the stainless steel brazing process can be extremely challenging. Cutting, drilling, soldering, and welding stainless steel is difficult mainly because the metal is a poor heat conductor and has a high rate of thermal expansion. It also reacts badly to excessive heat, causing it to warp. Thankfully, we have a unique line of products that can help make stainless steel soldering and brazing tasks easier.

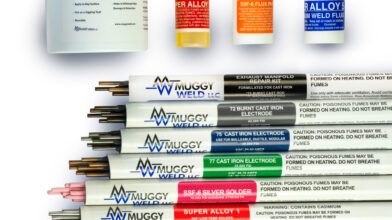

Super Alloy 1, SSQ-6, and SSF-6 silver solder are all designed for use with stainless steel. Allowing for easier and more effective repair and torch welding jobs, many of our products melt at high temperatures and can be used on a variety of metals, such as brass, copper, bronze, cast iron, and stainless steel. For soldering and brazing tasks, or for soldering and brazing stainless steel, SSQ-6 and SSF-6 can also be used with any heat source and can last for long periods with minimal care.

Meet Muggy Weld

Muggy Weld is committed to serving customers with high-quality electrodes and alloys for welding various metals, such as pot metal, aluminum, steel, and iron. If your organization values quality welding solutions, with little turnaround time and lower costs compared to traditional repairs, our rod and flux combinations consist of top-quality material and work in sync. You simply can’t go wrong with Muggy Weld for metal welding solutions.

Check Out Our Videos

View our videos to learn more about the stainless steel brazing process. We simplify this complex process by offering the proper resources and instruction. At Muggy Weld, we keep your best interest in mind. That’s why we don’t just provide products—we educate as well.

Welding stainless steel is an incredibly valuable skill to have due to its popularity. Learn everything you need to know about it down below.

| Super Alloy 1 Multi-Metal and Pot Metal Solder | SSF-6 High Strength 56% Silver Solder | SSQ-6 56% Silver Solder Paste | |

|---|---|---|---|

| Sizes Available (in.) | 3/32in, 1/8in | 1/16in | N/A |

| Sizes Available (mm) | 2.38mm, 3.17mm | 1.58mm | N/A |

| Melting temperature | 350°F (177°C) | 1150°F (622°C) | 1050°F (566°C) |

| Bonding strength | 20,000 PSI | Over 70,000 PSI | Over 85,000 PSI |

| Flux type and shelf life | Honey liquid, 2 year shelf life | Flux coated | Mixed in, 9 month shelf life |

| Recommended torch | Any | Any | Any |

| Color match? | Yes | Yes | Yes |

| Contains cadmium? | Yes | No | No |

| Works in all positions? | Yes | Yes | Yes |

| Will clean oxidized stainless? | |||

| Will wet to burnt stainless? | No | Yes | No |

| Will join stainless to brass, steel, copper, cast iron? | No | Yes | Yes |

| Can work as a jig? | No | No | Yes |

| Recommended for heat sensitive parts? | Yes | No | No |