Pot Metal Repair

Inexpensive casting alloys–also known as pot metal, monkey metal, or zinc die cast–have historically been difficult to work on because of their low melting point. Many pot metal repair rods melt at 700º F and can be dangerously close to melting the pot metal before you even apply them.

Super Alloy 1 pot metal restoration kit from Muggy Weld has a melting point of 350º F and unique properties that make repairing pot metal easier than ever before. Whether you’re soldering pot metal for a repair job or restoring original pot metal classic car parts, you can now work on these sometimes rare or irreplaceable parts with ease.

Even beginners can repair pot metal pitting and build up broken or missing pieces with a quality pot metal repair kit from Muggy Weld. The non-corrosive liquid flux acts as an exact temperature guide that turns root beer brown when the base metal reaches 350º F, preventing damage to the base metal. The resulting bond is 20,000 PSI and can be painted, powder coated, chrome plated, polished, or shaped.

Our pot metal restoration kit makes it possible for anyone to fix vintage car parts or antique statues, carburetors, clocks, Matchbox cars, jewelry, slot machines, juke boxes and more. Many auto enthusiasts believe real metal repair is a superior alternative to temporary epoxy repairs on their original pot metal parts. We carry Super Alloy 1 Multi-Metal and Pot Metal Solder, which bonds all types of white metals alone or in any combination.

Who We Are

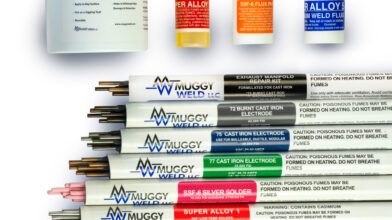

At Muggy Weld, we proudly provide high-quality electrodes and alloys for welding steel, aluminum, cast iron, pot metal, and various other metals. Our rod and flux combinations are made in the USA, composed of top-quality material and work synergistically. Does your organization want a faster turnaround time on repairs without breaking the bank? Look no further—our pot metal soldering kit is the ideal solution.

Educational Videos

We’ve provided videos for you to get up-to-speed on welding pot metal. While this process may be complex, having the proper knowledge and resources makes it possible for you to complete the job.

Learn everything you need to know about repairing pot metal here!

| 77 Non-Cracking Cast Iron Welding Rod | 72 Burnt Cast Iron Welding Rod | 75 Nickel Iron Rod for Malleable Ductile and Nodular Cast Iron | SSF-6 High Strength 56% Silver Solder | |

|---|---|---|---|---|

| Sizes Available (in.) | 5/32in, 1/8in, 3/32in | 5/32in, 1/8in, 3/32in | 3/32in, 1/8in, 5/32in | 1/16in |

| Sizes Available (mm) | 3.96mm, 3.17mm, 2.38mm | 3.96mm, 3.17mm, 2.38mm | 2.38mm, 3.17mm, 3.96mm | 1.58mm |

| Arc – TIG – Braze | Arc – TIG | Arc – TIG | Arc – TIG | Braze |

| Works on engine blocks? | Yes | No | No | Yes |

| Works on large cast iron holes? | Yes | Yes | Yes | No |

| Joins cast iron to steel? | Yes | Yes | Yes | No |

| Joins cast iron to metals other than steel? | No | No | No | Yes |

| Works on exhaust manifolds, woodstoves, or other burnt cast iron? | Good | Great | No | Good |

| Works on thin cast iron? | Yes | Yes | Yes | Yes, even very thin |

| Color match? | Good | Good | Good | No |

| All position? | Yes | Yes | Yes | Yes |

| Machineable? | Yes | No | Yes | Yes |

| Paintable? | Yes | Yes | Yes | Yes |

| Works over existing welds? | Fair– better on unwelded surface | Fair | Over nickel, yes | Great |

| Crack resistant? | Yes | No | No | Yes |

| Depth to bevel cracks | 3/4 through | 3/4 through | 3/4 through | 1/2 through |