Aluminum Repair Rods

These days, more and more parts are being replaced with aluminum parts. Why? Aluminum is lightweight, durable, and inexpensive in comparison with other metals. The problem is, most aluminum welding shops have been trained to believe that expensive machinery is needed to properly weld this versatile metal, leaving consumers in need of an easy way to weld aluminum.

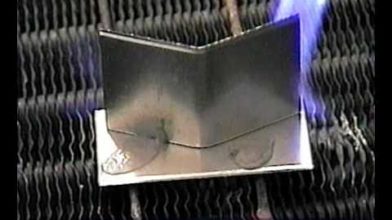

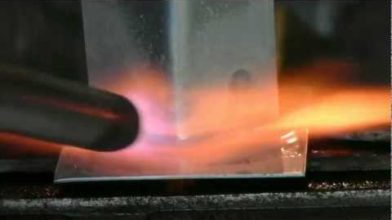

Aluminum melts at 1218°F and does not turn red like other metals before it reaches the point that it liquefies. If you have ever tried to weld aluminum you know that without an accurate temperature guide, you may end up cleaning aluminum off the floor. For this reason, many auto body shops previously recommended replacing aluminum parts rather than repairing them—which is not only expensive but unnecessary. Fortunately, times have changed, and there’s now a simple way to weld aluminum.

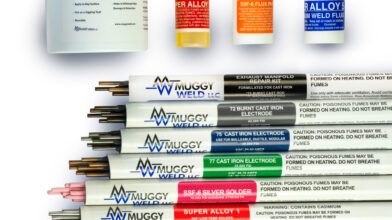

Muggy Weld’s aluminum welding, brazing, and soldering store contains a unique line of aluminum welding, brazing and soldering alloys and fluxes that work synergistically to act as an exact temperature guide when torch welding aluminum. While many aluminum brazing products are sold without flux, we believe the use of flux to be superior for several reasons.

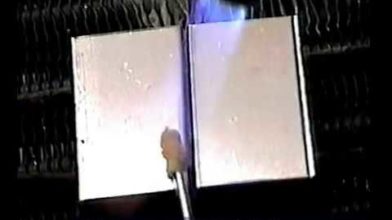

First, it allows the rod to flow and bond better than aluminum rod alone. Any welder knows that flow is an important factor in a successful aluminum soldering procedure.

“Where flux flows, rod goes”

Also, our flux acts as an exact temperature guide:

*Super Alloy 5 turns from powder to liquid at the exact moment when the rod should be applied

*Super Alloy 1 starts as a liquid and turns brown when ready for the rod.

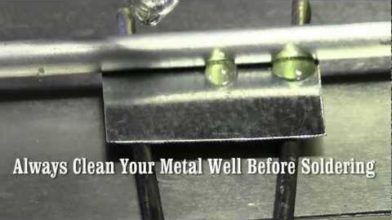

Finally, our Alloy 5 flux chemically reacts to clean up oxidation as well as other contaminants, which is very unique in aluminum repair procedure.

Browse Our Videos

View our videos down below to learn more about aluminum welding tips and techniques. It is easy to understand the aluminum welding process once it’s broken down with proper instruction and the right products. Muggy Weld has your best interest at heart, which is why we don’t just pride ourselves on our aluminum brazing store—we want to educate you on welding and soldering, too.

Whether you are welding close to heat sensitive materials and need a super low solder or are welding an aluminum boat and need a strong brazing rod, our welding alloys allow you to repair aluminum quickly, easily and inexpensively with your own torch at less than half the temperature aluminum melts. Muggy Weld has an aluminum welding rod to meet your needs.

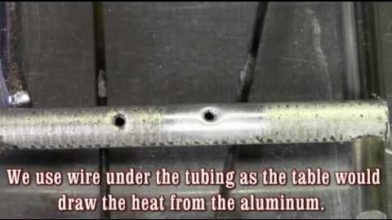

Note: Aluminum dissipates heat very quickly, therefore, oxyacetylene and Super Alloy 5 are required for all thick aluminum or large masses of aluminum.

| Super Alloy 1 Multi-Metal and Pot Metal Solder | Super Alloy 5 Aluminum Welding and Brazing Rod | |

|---|---|---|

| Sizes Available (in.) | 3/32in, 1/8in | 3/32in, 1/16in |

| Sizes Available (mm) | 2.38mm, 3.17mm | 2.38mm, 1.58mm |

| Melting Point | 350° F (177° C) | 600° F (316° C) |

| Bonding Strength | 20,000 PSI | 30,000 PSI |

| Flux type and shelf life | Honey liquid, 2 year shelf life | Powder, 1 year shelf life |

| Recommended torch | Propane, MAPP, butane, oxyacetylene on larger or thicker pieces | Propane, MAPP, oxyacetylene on larger or thicker pieces |

| Can be polished? | Fair | Excellent |

| Can be plated? | Yes | Yes |

| Takes powder coating? | Fair | Excellent |

| Can be used on thick aluminum? | No | Yes, with oxyacetylene |

| Can join aluminum to other metals (brass, steel etc)? | Yes | No |

| Can repair radiators without burning fins? | Yes | No |

| Potential for metal warpage? | No | Potential |

| Can be used with TIG? | No | Yes |

| Can repair cast aluminum? | No | Yes, with oxyacetylene |

| Pre-cleaning necessary? | Yes | Yes |

| Can repair aluminum boats? | No | Yes, with oxyacetylene |

| Can be anodized? | No | Yes |

| Can be used with a soldering iron? | Yes | No |

| Demonstrated on pop cans at the county fair? | NEVER | NEVER |