Steel is an alloy composed of iron and carbon—the higher the carbon content, the stronger, harder and more brittle the steel. There are many types of steel that can be used for the steel brazing process, all of which are categorized based upon various physical properties and carbon content. High carbon steel is very strong, and it is used for files, cold chisels, and various metal tools while low carbon steel is used for tubing, nails, and castings.

Before you start repairing steel, you will have to first determine the weldability of the metal. This is inversely proportional to its ability to be hardened by heat. Basically, this means that varieties of the metal with fewer alloying agents can easily be welded better than others.

Next, measure the equivalent carbon content of the different alloys of steel. This compares the properties of any steel alloy to those found in ordinary carbon steel. If possible, use only high strength, low-alloy metals specifically designed for torch brazing steel.

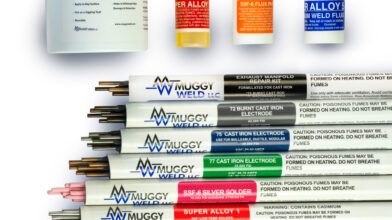

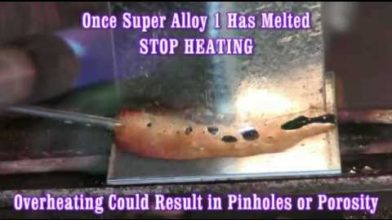

Most jobs require only a hand-held propane torch. Super Alloy 1 is recommended when heat or aesthetics is an issue. Otherwise, we recommend our SSF-6 Silver Solder for torch welding: with a holding strength of 71,000 PSI, SSF-6 is as strong as a MIG or TIG weld, with a beautiful finish.

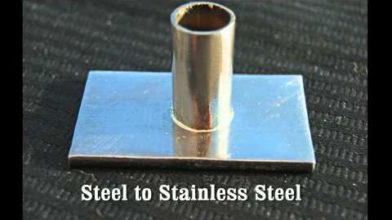

Steel repair on stainless steel can be very difficult; it is difficult to cut and is prone to distortion because of its high thermal expansion. Control the amount of ferrite in the weld to minimize hot cracking, preheat, and use steel brazing and solder products such as Super Alloy 1, SSF-6, and SSQ-6 when working on different types of stainless steel.

Browse Our Videos

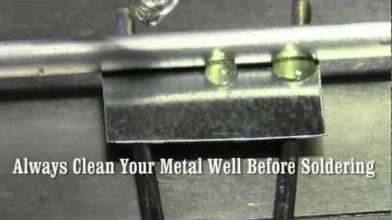

Muggy Weld has several videos on steel soldering and brazing below to help clarify the process. We care about providing you with not only welding solutions but also educational resources to become more confident about making repairs. Our videos will instruct you on everything you need to know about steel soldering and brazing.

| Super Alloy 1 Multi-Metal and Pot Metal Solder | SSF-6 High Strength 56% Silver Solder | SSQ-6 56% Silver Solder Paste | |

|---|---|---|---|

| Sizes Available (in.) | 3/32in, 1/8in | 1/16in | N/A |

| Sizes Available (mm) | 2.38mm, 3.17mm | 1.58mm | N/A |

| Melting temperature | 350° F (177° C) | 1150° F (621° C) | 1050° F (566° C) |

| Bonding strength | 20,000 PSI | Over 70,000 PSI | Over 85,000 PSI |

| Flux type and shelf life | Honey liquid, 2 year shelf life | Flux coated | Mixed in, 9 month shelf life |

| Recommended torch | Propane, MAPP, butane, oxyacetylene | Any | Any |

| Contains cadmium? | Yes | No | No |

| Color match? | No | Good | Good |

| Works in all positions? | Yes | Yes | Yes |

| Works for heat sensitive parts? | Great | Fair | Fair |