Welding is a trade used in several different industries, and the results are essential for some such as shipbuilding and aerospace. Without it, the structures built in these industries would be nearly impossible to create. As different technologies continue to evolve, so must the tools we use to craft them.

The history of welding goes back farther than our history books can track. Early examples include 1330 B.C.; even Egyptians would practice metal welding. It’s taken thousands of years for the craft to become what it is now, and we’re still refining it today. In this article, we take a look into the history of welding and the milestones that served to improve the art.

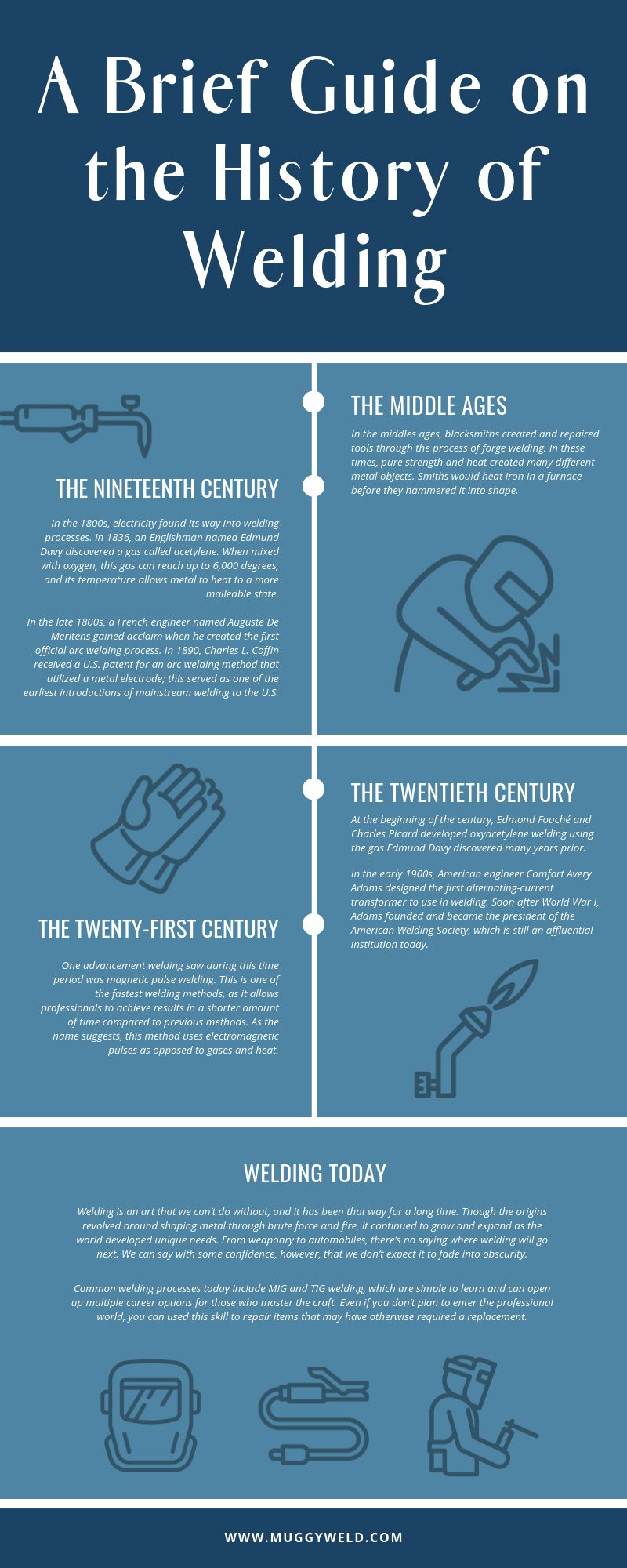

The Middle Ages

Many of us first learn about welding through examples of blacksmiths in picture books. In the middles ages, blacksmiths created and repaired tools through the process of forge welding. In these times, pure strength and heat created many different metal objects. Smiths would heat iron in a furnace before they hammered it into shape. The metal would often get reheated and worked on until any imperfections were hammered away.

The Nineteenth Century

In the 1800s, electricity found its way into welding processes because of the many scientific discoveries that took place during this time period. Chemist Sir Humphry Davy was the first man credited with producing an electric arc with carbon rods. He would touch them together to create an electric current and pull them slightly apart.

In 1836, an Englishman named Edmund Davy discovered a gas called acetylene. When mixed with oxygen, this gas can reach up to 6,000 degrees, and its temperature allows the metal to heat to a more malleable state. The gas would not be utilized until decades later after Davy’s death, though, when two inventors create oxyacetylene welding.

In the late 1800s, a French engineer named Auguste De Meritens gained acclaim when he created the first official arc welding process. Although this did not reach the correct temperatures to weld steel, it became widely used for lead plates to manufacture batteries. In 1881, Meritens received a French patent for this welding process.

In 1890, Charles L. Coffin received a U.S. patent for an arc welding method that utilized a metal electrode; this served as one of the earliest introductions of mainstream welding to the U.S.

The Twentieth Century

While the 1800s laid some of the foundations for welding, many processes really found their footing in the 20th century. At the beginning of the century, Edmond Fouché and Charles Picard developed oxyacetylene welding using the gas Edmund Davy discovered many years prior. It wasn’t until their contribution to the process that metal could reach a temperature hot enough to actually melt.

Fouché and Picard developed a method that allowed a flame to reach temperatures twice as hot as it could prior to this discovery. The men introduced oxyacetylene welding in 1903, and it rapidly gained traction. Though we’ve since discovered faster methods to weld, we cannot discount the contribution these two men made to the art. Their discovery revolutionized welding processes, and their discovery changed this industry forever.

In the early 1900s, American engineer Comfort Avery Adams took an interest in welding. His interest increased America’s investment in the art, especially when utilized for shipbuilding. Adams also designed the first alternating-current transformer to use in welding. Soon after World War I, Adams founded and became the president of the American Welding Society, which is still an affluential institution today. Adams was presented with several awards for his efforts toward expanding welding technology.

Adams was not the only welding pioneer that produced work at the beginning of the 20th century, though. Many give credit for the alternating-current transformer design to Adams, but C.J. Holslag is said to have actually created it. It would be several years, however, before Holslag’s efforts came to fruition.

The mid-nineteenth century saw developments and patents for methods such as heliarc welding and GAS shielding. Minor adjustments were made to existing and newly discovered processes as the art continued into the 2000s.

The Twenty-First Century

One advancement welding saw during this time period was magnetic pulse welding. Though we can see early developments from Russian scientists in the 1970s, it wasn’t until recently that industry professionals implemented this method. This is one of the fastest welding methods, as it allows professionals to achieve results in a shorter amount of time compared to previous methods. As the name suggests, this method uses electromagnetic pulses as opposed to gases and heat. While many consider this process a revolutionary concept, it still requires further refinement.

Laser-arc-hybrid is a form of welding that many people use to replace what some consider more archaic methods. This method attracts many because of the stability and deep penetration it offers. While laser-arc-hybrid also allows room for future improvements, many speculate it will soon become the preferred method in many industries.

Welding Today

Welding is an art that we can’t do without, and it has been that way for a long time. Though the origins revolved around shaping metal through brute force and fire, it continued to grow and expand as the world developed unique needs. From weaponry to automobiles, there’s no saying where welding will go next. We can say with some confidence, however, that we don’t expect it to fade into obscurity.

Common welding processes today include MIG and TIG welding, which are simple to learn and can open up multiple career options for those who master the craft. Even if you don’t plan to enter the professional world, you can used this skill to repair items that may have otherwise required a replacement.

The Products You Deserve

At Muggy Weld, we strive to provide consumers with the high-quality products they need and deserve. We’re a welding equipment supply company that seeks to provide individuals and companies alike with products that will get the job done right. If you have any questions, or would like to make a purchase, contact Muggy Weld.