Spring lets you live life to the fullest! Conquering the waters with your boat is just another blessing of spring. But after sitting idle throughout the long winter, your boat demands some attention, especially if the boat is made of aluminum. Aluminum boat maintenance is a bit different. The amount of yearly upkeep tasks depends on your ongoing aluminum boat maintenance, which may include welding or brazing the boat itself.

This article can work as a complete guide for you to get your aluminum boat ready to rock after a long winter. We have included some crucial tips on de-winterizing your aluminum boat in the latter part of the article.

How to Perform Aluminum Boat Maintenance for Spring?

Getting your aluminum boat ready for spring involves proper attention, meticulous inspection, and some hard work. If you are confident, you can do it alone, or you can do it with some assistance from a maintenance professional.

Check the Hull

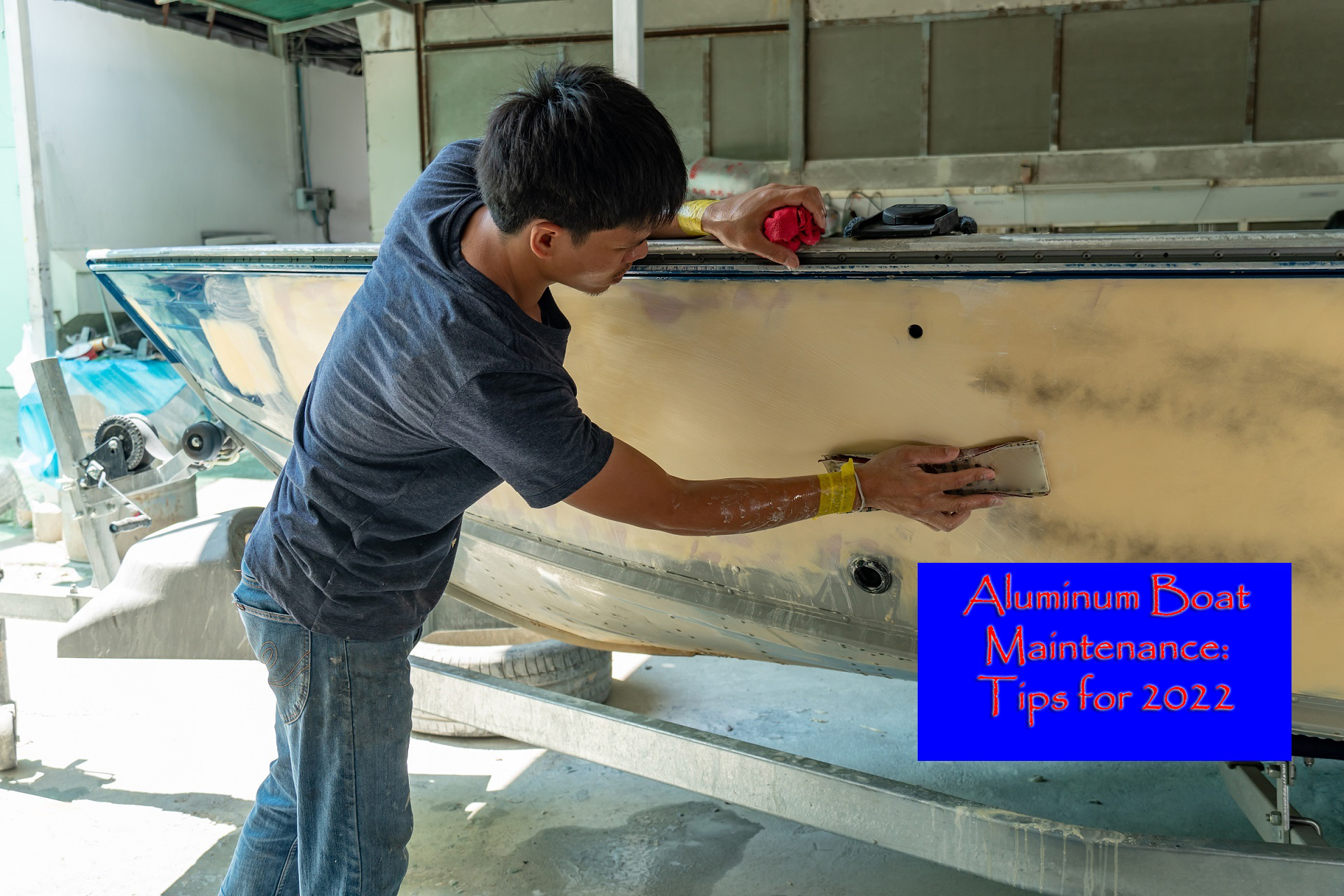

Since your boat was covered for months, anything could have happened to it by this period. The most vulnerable part of your boat is the hull. Your boat’s ability to float on water mostly depends on the well-being of the hull. So, the first step in checking your boat after the winter should be inspecting the hull thoroughly.

During the inspection, look for any cracks, moisture accumulation, or damage to the hull of your boat. If you find water in the hull, it may indicate cracks. Identify the need for painting. Replace the zincs if more than half of it is gone. Carefully check the hull for any need for repair of dings, dents, or any damaged seams.

Repair the Hull

If you find any damage to the dings, dents, or seams of the hull, do not hesitate to repair them immediately. Aluminum boat repair is a bit different than the maintenance of other boats, due to the difficulty in welding large masses of aluminum. Make sure to follow the correct procedure to ensure the safety of your water adventures.

You should always use quality materials to repair the hull of the aluminum boat. For that, you can rely on Super Alloy 5 Aluminum Repair Rods, produced by Muggy Weld LLC. You can weld, solder, or braze any damage to your boat with them. These aluminum rods can work with any torch, including oxyacetylene, MAPP gas, natural gas, or propane.

Inspect the Engine

Like any motorized vehicle, your aluminum boat’s performance heavily depends on the engine. After a long rest, the engine can grow any type of problem that is out of your imagination. First, check the status of the engine oil. We hope you changed the engine oil and filter before putting your boat to rest at the beginning of the winter. That is the standard maintenance procedure.

If the engine oil has grown a frothy texture, there might be water in it. It may indicate a serious engine problem. We suggest consulting a professional in that situation. You should also reinstall the engine battery and check all the electrical connections.

Paint the Boat

To prevent any growth at the bottom and on the sides of your aluminum boats, you should paint it properly. It is very important to ensure a long life for your boat when you need to keep it in the water for a long time.

However, any type of paint will not be able to save your aluminum boat. You must use anti-fouling paint to confirm the boat’s durability.

Get a Professional Check-Up

It doesn’t matter if you have prepared your aluminum boat for the spring all by yourself or with someone else’s help. You must check every safety issue of the vehicle by a maintenance professional expert before taking the boat into the water.

You can be as confident about your repair job as you please. But it is the job of a professional to duly follow the standard procedures and check if the vehicle is ready for water or not.

7 Tips to De-Winterize Aluminum Boats

Here we have listed 7 tips about de-winterizing your aluminum boat. We think they can be very helpful to track yearly aluminum boat maintenance tasks:

- Change the Safety Gears: The life jackets, fire extinguishers, flares, and other safety gears have been there untouched and unused for months. It is wise to change them all no matter how new they look. After all, it is a matter of your life!

- Follow State Regulations: Make sure to comply with all the rules and regulations of federal and state governments on plying water vehicles. For example, all children need to wear floating gear which is approved by the U.S. Coast Guard.

- Use Corrosion Inhibitors: At all the joints of all the metal parts of your aluminum boat, apply corrosion-inhibitor agents. It will ensure a longer life for the boat.

- Carry Extra Fuel Filter: Carrying an extra fuel filter can save you from many awkward situations in the water. Also, you should inspect the fuel filter before every journey.

- Mind the Cushions: The cushions of your boat can also work as flotation devices in a time of emergency. So, do not forget to make sure they are in good condition before sailing the boat.

- Duct Tapes & Garbage Bags: You should always be prepared for the worst scenario. Big garbage bags along with duct tape can save your life by stopping water leaks. You should always take them in the water.

- White Vinegar: You will be surprised to know the versatile use of white vinegar. Apart from being a good ingredient in your foods, they can save you from uncomfortable itchiness if you get in contact with a jellyfish or pesky mosquitoes.

Repair Any Dents, Dings And Damaged Seams With Muggy Weld

Aluminum boat repair is essential before you set out on the spring waters. No matter how good you are at aluminum boat maintenance, rust and defects do occur over the winter. So, proper checking and repair is a must.

But you are going to need high-quality supplies for the repair as only that can ensure the highest longevity of your boat. We at Muggy Weld provide only the most pristine maintenance welding supplies that you can use to get your boat back into tip-top shape. So, take a look at our welding supply collection and order what you need to begin your aluminum boat maintenance process.