Every welding application is different, but you can rest assured that our site will empower you with the knowledge and products you need to improve business operations. Plus, proper welding eliminates the expense of total repairs—learn more about our welding supplies online.

Who We Are

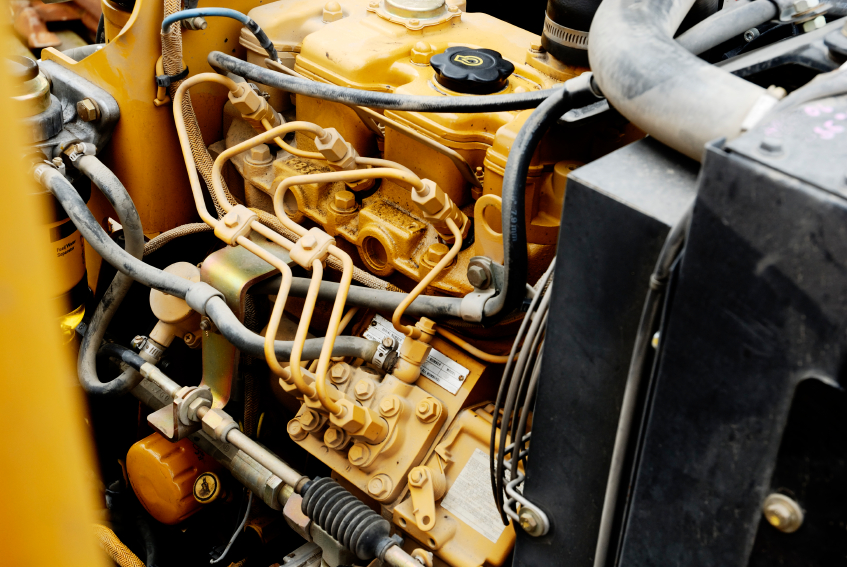

Muggy Weld provides high-quality alloys and electrodes for welding aluminum, pot metal, cast iron, steel, and various other metals. Our rod and flux combinations boast high-quality composition and work synergistically, making them perfect for organizations who want to save time and money on repairs.

Unique Product Benefits

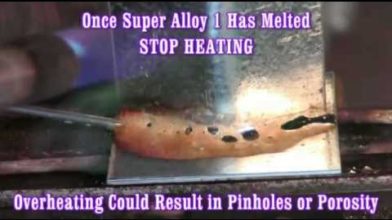

There are several welding products on the market, but ours possess unique benefits. For instance, our electrodes for cast iron welding have a softer, highly machinable metallurgical makeup, allowing for added weld elongation. Additionally, our Super Alloy 1 pot metal restoration kit has a cooler melting point than many other rods, making pot metal application easier. We pride ourselves on providing top products that eliminate downtime and costs—you can always count on Muggy Weld.

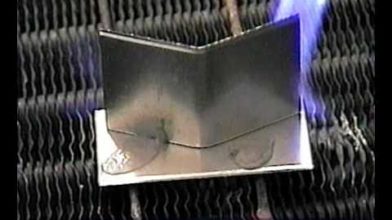

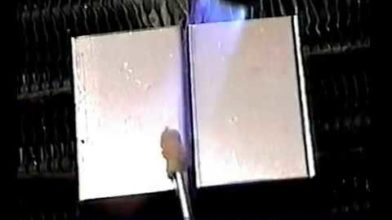

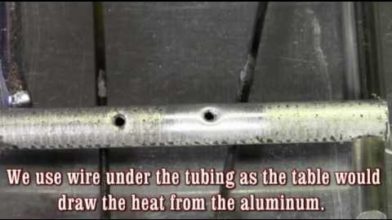

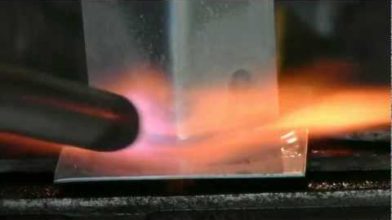

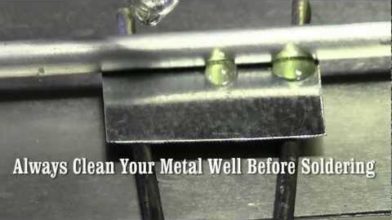

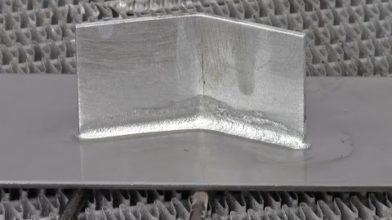

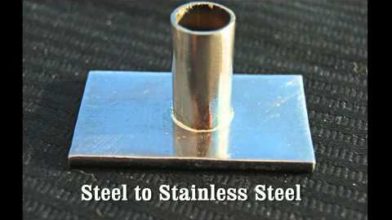

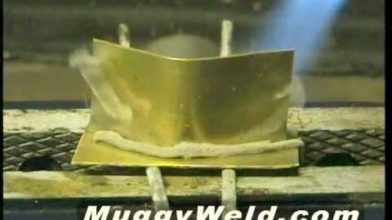

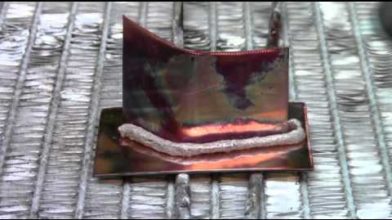

Flip Through Our Videos

Having a visual aid is always helpful. We have provided an assortment of videos for you to learn about or brush up on welding techniques. Simply choose the topic you are interested in, and we will provide you with everything you need to know. It is one thing for a welding company to provide products—Muggy Weld likes to go above and beyond by offering educational resources.

Welding is not an easy process, but the right information can help you master MIG, TIG, arc, or other techniques. Whether you are performing cast aluminum repair, cast iron repair, stainless steel welding, or welding for just about anything else, our solutions will make life easier.

Check out The Muggy Weld Knowledge Center to learn more about our online welding supplies.